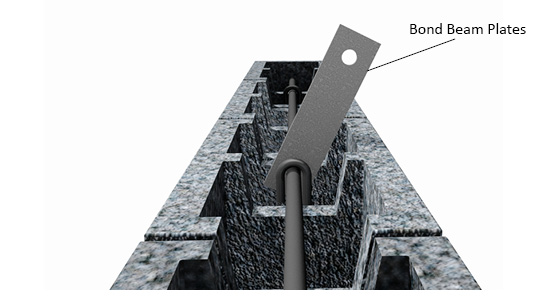

Bond Beam

Heavy duty hot dip galvanised brackets used for heavy duty tie downs

1. Feed horizontal steel reinforcement bar through the hole on the side of Bond Beam Plate that is to be cast in.

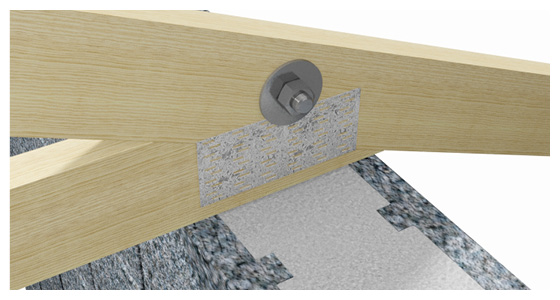

3. Fix trusses to Bond Beam Plates with M12 or M16 bolts through truss top chords. Bolt must be located above the nailplate at the heel.

2. Fix N12 vertical reinforcement bars close as possible to the Bond Beam Plates and anchor them to foundation. Bond Beam Plates to be positioned where truss is to be supported.

4. Use 3.0mm thick Ø55mm round washers or 50mm square washers to timber side, as per AS1720.1-2010

Product Specification |

Product Code |

200 x 50 x 6mm with 14 & 17mm Holes - Hot Dipped Galvanised |

BBB2001417G |

200 x 50 x 6mm with 14 & 19mm Holes - Hot Dipped Galvanised |

BBB2001419G |

200 x 50 x 6mm with 17 & 17mm Holes - Hot Dipped Galvanised |

BBB2001717G |

200 x 50 x 6mm with 17 & 19mm Holes - Hot Dipped Galvanisedn) |

BBB2001719G |

250 x 50 x 6mm with 14 & 17mm Holes - Hot Dipped Galvanised |

BBB2501417G |

250 x 50 x 6mm with 17 & 17mm Holes - Hot Dipped Galvanised |

BBB2501717G |

250 x 50 x 6mm with 17 & 19mm Holes - Hot Dipped Galvanised |

BBB2501719G |

Thickness: |

6.0mm |

Material: |

Hot dipped galvanised corrosion protection |