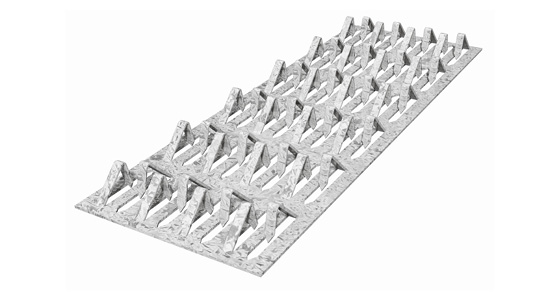

Cluster Knuckle Plate

Classic Australian manufactured cluster nail plates allow for all kinds of connecting projects with easy hammer installation

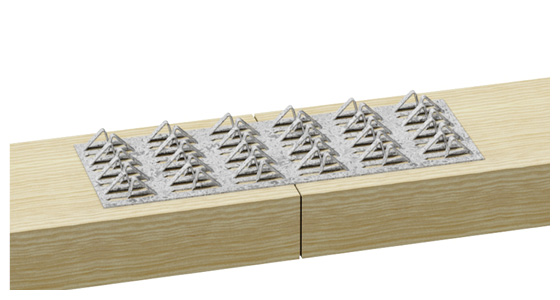

Applying the Cluster nail is very simple as no special pressing equipment is needed.

The Cluster nail’s teeth can be driven into a piece of timber using a normal carpenter’s hammer on site by tradespersons, home owners and builders.

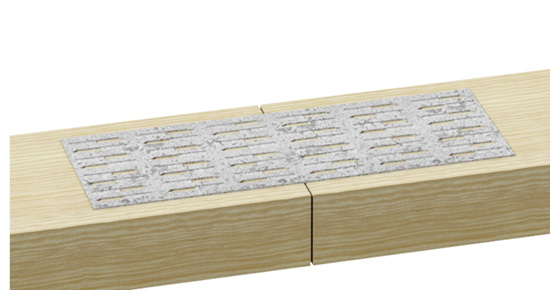

The Cluster nail teeth should now be embedded securely into the timber, subsequently joining the two separate pieces of timber together.

Cluster nails are suitable for all softwoods and some unseasoned hardwood timbers. Difficulty may be experienced when driving into seasoned hardwood and some unseasoned hardwood timber.

Step 2.

Using a carpenter’s hammer, drive the protruding teeth into the timber. For butt joining, turn the timber over and repeat the process on the other side.

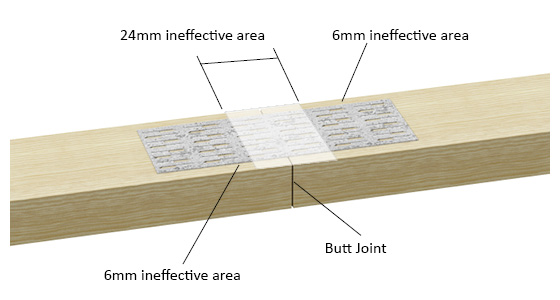

In timber joint design, nails within 6mm of timber edges or within 12mm of timber ends are regarded as ineffective. As the nail rows in the Cluster nail are 32mm apart, all nails, fixed symmetrical over the joint are effective.

Product Specification | Product Code |

|---|---|

33 x 127 x 1mm Galvanised | BCT4-4 |

33 x 190 x 1mm Galvanised | BCT4-6 |

44 x 127 x 1mm Galvanised | BCT5-4 |

44 x 190 x 1mm Galvanised | BCT5-6 |

67 x 127 x 1mm Galvanised | BCT8-4 |

67 x 190 x 1mm Galvanised | BCT8-6 |

67 x 254 x 1mm Galvanised | BCT8-8 |

89 x 63 x 1mm Galvanised | BCT10-2 |

89 x 127 x 1mm Galvanised | BCT10-4 |

89 x 190 x 1mm Galvanised | BCT10-6 |

89 x 254 x 1mm Galvanised | BCT10-8 |

89 x 317 x 1mm Galvanised | BCT10-10 |

133 x 127 x 1mm Galvanised | BCT16-4 |

133 x 190 x 1mm Galvanised | BCT16-6 |

133 x 254 x 1mm Galvanised | BCT16-8 |

Thickness: | 1.0mm |

Material: | G300-Z275 |